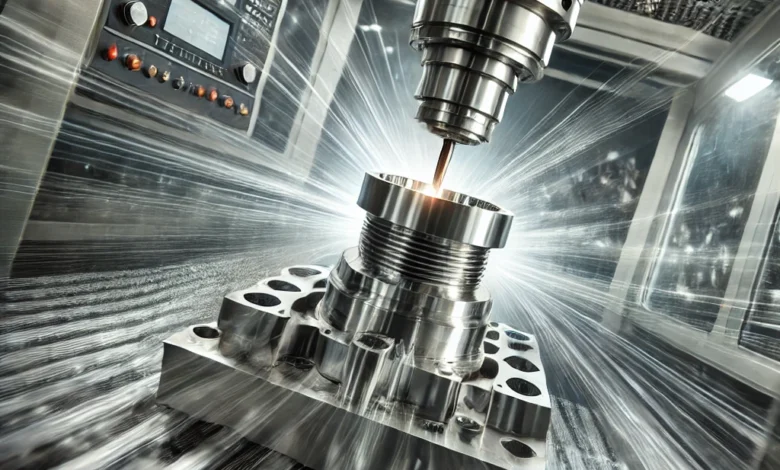

Discover Top-Quality CNC Machining Services for Your Complex Projects

CNC machining is revolutionizing industries by providing precision, efficiency, and flexibility in the manufacturing process. Whether you’re creating intricate parts for aerospace, automotive, or medical applications, CNC machining services ensure that your complex projects are completed with unmatched accuracy and reliability. But what exactly makes CNC machining stand out, and how can it benefit your projects? In this blog, we explore the many advantages of CNC machining services and why they are a critical component of modern manufacturing.

What is CNC Machining?

At its core, CNC machining is a manufacturing process that uses computerized control to operate machine tools, such as lathes, mills, routers, and grinders. CNC stands for Computer Numerical Control, which refers to the use of software to direct machine operations. Unlike manual machining, CNC machines are capable of producing parts with incredible precision and repeatability, making them ideal for both simple and highly complex designs.

The ability to automate the machining process reduces human error, increases speed, and allows for the production of high-quality parts in a shorter timeframe. In fact, many industries rely on CNC machining to meet tight tolerances and strict specifications for a variety of products, from small components to large, intricate assemblies.

Why Choose CNC Machining Services for Complex Projects?

When you have a complex project that requires intricate details, precise cuts, or tight tolerances, CNC machining services are your best option. CNC machining is designed to handle the most demanding requirements, providing solutions that other manufacturing processes simply can’t.

One of the most significant advantages of CNC machining is its versatility. It allows manufacturers to work with a wide range of materials, including metals (aluminum, stainless steel, titanium), plastics, and even composites. CNC machines can produce parts in almost any shape or size, from simple geometric shapes to highly intricate designs with multiple features. This adaptability makes CNC machining ideal for industries that require customized or specialized parts, such as the automotive, aerospace, medical, and electronics industries.

Additionally, CNC machines are incredibly efficient. Once programmed, they can run continuously, producing parts with consistent quality and speed. This makes CNC machining a cost-effective solution, particularly when producing large batches of parts that require high levels of precision. Even with complex designs, CNC machining services provide rapid turnaround times and maintain strict adherence to specifications.

The Benefits of CNC Machining Services

- Precision and Accuracy

One of the most compelling reasons to opt for CNC machining services is the level of precision they offer. CNC machines can produce parts with tolerances as tight as a few microns, ensuring that even the most intricate designs are perfectly executed. This is especially important when producing parts that need to fit together or function in highly demanding environments, such as in the aerospace or medical sectors.

- Efficiency and Speed

CNC machining is known for its speed and efficiency. Once a design is programmed into the machine, it can produce parts quickly, with minimal downtime between runs. This is particularly advantageous when manufacturing large quantities of parts, as it reduces production time and costs. Furthermore, CNC machines can operate 24/7, ensuring that projects are completed within the shortest possible time frame.

- Flexibility and Customization

With CNC machining, manufacturers have the ability to customize parts to meet specific project requirements. Whether you need a one-off prototype or a full-scale production run, CNC machines can handle both small and large orders with ease. This flexibility makes CNC machining ideal for industries that require unique or custom-made components.

- Quality and Consistency

The automated nature of CNC machining ensures that each part is produced to the same high standards. With computerized controls and minimal human intervention, CNC machining services eliminate the risk of human error, resulting in consistently high-quality parts. This consistency is vital for industries that require high-performance components, such as in the manufacturing of medical devices or high-precision automotive parts.

- Reduced Waste and Material Efficiency

Another significant advantage of CNC machining is its ability to reduce material waste. The high precision of CNC machines means that parts are made with minimal excess material, which can help reduce costs and make the process more environmentally friendly. This is particularly important in industries where the cost of raw materials is high, such as aerospace or automotive manufacturing.

Industries That Benefit from CNC Machining Services

CNC machining is a versatile technology that finds applications across a wide range of industries. Let’s take a closer look at some of the sectors that benefit the most from CNC machining services:

1. Aerospace Industry

The aerospace industry requires components that are not only precise but also able to withstand extreme conditions. CNC machining is essential for producing parts like engine components, brackets, housings, and landing gear. The ability to work with high-strength materials, such as titanium and Inconel, makes CNC machining ideal for the aerospace sector.

2. Automotive Industry

CNC machining plays a critical role in the production of automotive components, from engine parts to interior details. Whether it’s for mass production or specialized custom parts, CNC machining provides the accuracy and speed needed to meet the high standards of the automotive industry. CNC machines can create parts that are lightweight yet durable, ensuring high performance and safety.

3. Medical Industry

In the medical field, precision is paramount. CNC machining services are used to produce surgical instruments, implants, and prosthetics, all of which must meet the strictest standards of quality and accuracy. The ability to create complex geometries and work with biocompatible materials makes CNC machining indispensable in medical manufacturing.

4. Electronics Industry

The electronics industry also relies heavily on CNC machining for producing components like connectors, casings, and circuit boards. As electronics become smaller and more complex, the need for high-precision parts has increased, making CNC machining the perfect solution. The technology allows for the production of small, intricate parts with exceptional accuracy, meeting the demands of modern electronic devices.

5. Defense Industry

CNC machining is critical for producing defense-related components, such as firearms, ammunition, and military vehicles. The ability to work with tough materials and produce parts that meet exact military specifications makes CNC machining indispensable in the defense sector.

Whether you have complex or simple requirements, https://www.premiumparts.com/ offers top-tier CNC machining services tailored to meet your exact specifications.

The Process of CNC Machining

CNC machining is a multi-step process that begins with the creation of a 3D model or a CAD (computer-aided design) file. This design is then translated into instructions that the CNC machine can follow. Here’s a brief overview of the typical CNC machining process:

Step 1: Design and Programming

The first step in the CNC machining process is to create a 3D model of the part. Using CAD software, designers can create highly detailed models that are ready for machining. Once the design is complete, the file is converted into a set of instructions that the CNC machine can follow. These instructions are generated using CAM (computer-aided manufacturing) software.

Step 2: Material Selection

After the design is ready, the appropriate material is selected for the part. CNC machining can work with a wide variety of materials, including metals, plastics, and composites. The material must be chosen based on the part’s intended function and the environment it will operate in.

Step 3: Machining Process

Once the material is prepared, the CNC machine begins the machining process. This involves cutting, drilling, and shaping the material to the exact specifications outlined in the CAD model. The machine uses various tools, including drills, end mills, and lathes, to remove material and create the final shape.

Step 4: Finishing and Quality Control

After the part is machined, it undergoes finishing processes, such as polishing, coating, or heat treatment, to improve its appearance and performance. The final part is then inspected to ensure it meets all specifications and tolerances. Quality control is an essential part of the CNC machining process, ensuring that each part is produced to the highest standards.

How to Choose the Right CNC Machining Service for Your Project

Choosing the right CNC machining service is critical to the success of your project. Here are some factors to consider when selecting a provider:

- Experience and Expertise: Look for a provider with a track record of working with your industry and type of project. Experienced CNC machining services will have the knowledge and skills to handle complex requirements.

- Technology and Equipment: The quality of CNC machines and software used by the provider can greatly affect the accuracy and efficiency of the machining process. Ensure that the provider has state-of-the-art equipment.

- Quality Control: Make sure that the provider follows strict quality control procedures to ensure that your parts meet all specifications.

- Lead Times: Consider the lead times for production and delivery. A reliable CNC machining service will be able to meet your deadlines without compromising on quality.

- Customer Support: Good customer support is essential for troubleshooting issues and ensuring that your project runs smoothly from start to finish.

Conclusion

In conclusion, CNC machining is an indispensable tool for modern manufacturing, offering unparalleled precision, flexibility, and efficiency. Whether you’re working on simple or complex projects, CNC machining services provide solutions that meet the highest standards of quality and performance.