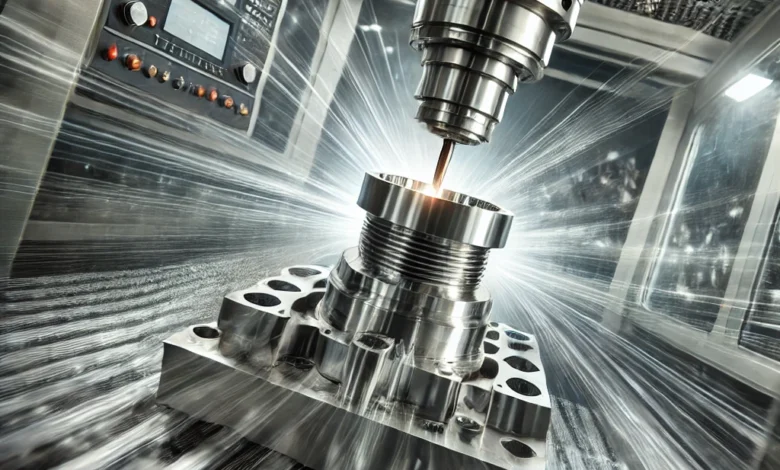

Unlock Precision and Efficiency with CNC Machining Services

CNC machining, short for Computer Numerical Control machining, has revolutionized manufacturing and precision engineering. This cutting-edge technology allows manufacturers to create highly accurate and intricate parts by using automated processes that are controlled by computer software. CNC machining offers significant advantages over traditional manufacturing techniques, enabling the production of complex components with precision, speed, and efficiency. Whether you’re producing prototypes, one-off parts, or large production runs, CNC machining can dramatically improve the quality and reliability of your output. In this article, we’ll dive deep into the benefits of CNC machining, how it works, and why it’s essential for industries ranging from aerospace to automotive.

The Basics of CNC Machining

At its core, CNC machining is a process where pre-programmed computer software controls the movement of machinery and tools to create precise parts and components. CNC machines can perform various tasks, including drilling, milling, turning, and grinding, all with incredible accuracy. One of the most compelling reasons why CNC machining is so widely used is its ability to produce parts with tolerances down to a few microns.

CNC machining is highly versatile, offering a wide range of possibilities for creating everything from small, intricate components to large, heavy-duty parts. The machinery used in CNC processes is highly advanced, often equipped with multiple axes to ensure that the tools can move in various directions, thus allowing for the creation of highly complex geometries. Some CNC machines even feature multiple tools that automatically change, making the machining process even more efficient.

Unlike traditional methods where operators have to manually adjust settings, CNC machining uses pre-programmed software to control the machines, minimizing human error and ensuring that each part is produced with the same level of precision. This level of automation allows manufacturers to meet high-quality standards consistently, with little to no deviation between individual parts.

Advantages of CNC Machining

CNC machining offers a myriad of benefits, making it one of the most popular manufacturing processes today. Let’s explore the key advantages:

1. Precision and Accuracy

The most significant advantage of CNC machining is its precision. CNC machines can produce parts with incredibly tight tolerances, often in the range of a few thousandths of an inch. This is crucial in industries where even the smallest error can lead to catastrophic consequences, such as aerospace, automotive, or medical device manufacturing.

The precision of CNC machining ensures that parts fit perfectly together, reducing the risk of costly errors during assembly. It also eliminates the need for secondary operations, saving both time and money. The consistent accuracy of CNC machines makes them an ideal choice for mass production, where uniformity across parts is essential.

2. Increased Efficiency and Productivity

CNC machines are highly efficient because they can operate continuously, often running 24/7 with minimal downtime. This significantly increases the productivity of manufacturing processes. The automation provided by CNC machining eliminates much of the manual labor involved, allowing skilled workers to focus on other tasks, such as programming or inspecting parts.

The ability to set up the machine with the exact parameters needed for each job also reduces setup time, enabling faster turnaround times and quicker production cycles. For industries that require rapid prototyping or quick turnaround on parts, CNC machining is a game-changer.

3. Cost-Effective Production

While CNC machines themselves can be expensive, they offer significant long-term savings. Because CNC machining minimizes human intervention and reduces the chances of errors, it leads to fewer defects and rework costs. Additionally, CNC machines can perform multiple tasks simultaneously, reducing labor costs and the need for multiple machines.

In the long run, the high-speed production and minimal waste associated with CNC machining can result in a more cost-effective manufacturing process. This is especially beneficial for businesses that need to produce large quantities of parts.

4. Flexibility and Customization

One of the standout features of CNC machining is its flexibility. The same CNC machine can be programmed to produce a wide variety of parts, meaning that manufacturers can quickly switch between different designs and components without needing to invest in new equipment.

Furthermore, CNC machining allows for custom parts and unique designs, making it an ideal solution for industries that require tailored solutions. Whether it’s a one-off prototype or a small batch production run, CNC machining can adapt to meet specific needs, ensuring that each part is made to the exact specifications.

CNC Machining in Rapid Prototyping

Rapid prototyping is a key application of CNC machining, and it plays a pivotal role in product development. Prototyping involves creating a model of a product or part in a short period to test its design and functionality before mass production begins. With CNC machining, designers can quickly create prototypes with high precision, helping to refine product designs and minimize costly errors in the manufacturing phase.

CNC machining enables designers to produce functional prototypes made from the same material that will be used in final production. This gives a more accurate representation of how the part will perform in the real world. Prototypes can be tested for fit, function, and durability before moving to full-scale manufacturing, saving both time and resources.

The flexibility of CNC machines also allows for rapid modifications. If changes need to be made to a design, CNC machines can be reprogrammed quickly to create a new version of the prototype, significantly shortening the product development cycle.

Key Industries Benefiting from CNC Machining

CNC machining is not just beneficial for one industry; it has applications in a wide range of sectors. Here are some of the key industries that leverage CNC machining services:

1. Aerospace

In aerospace, precision is paramount. CNC machining ensures that each component—whether it’s an engine part, wing structure, or landing gear—is manufactured to the highest standards. The aerospace industry requires tight tolerances and high-performance materials, and CNC machining can deliver on both fronts. It also helps streamline the manufacturing process, allowing for faster production times and reduced costs.

2. Automotive

The automotive industry relies heavily on CNC machining for everything from engine components to structural parts. CNC machining ensures that each component is made with the highest level of accuracy, which is critical for safety, performance, and durability. The automotive industry also uses CNC for rapid prototyping to test new designs quickly before full-scale production.

3. Medical Devices

CNC machining is instrumental in producing medical devices that require high levels of precision and reliability. From surgical tools to implants, CNC machining ensures that medical parts are fabricated to meet strict regulatory standards. The ability to work with biocompatible materials and maintain strict tolerances is crucial in the medical field.

4. Electronics

In the electronics industry, CNC machining is used to create precision parts such as connectors, housings, and brackets. The ability to work with small, complex parts is essential, and CNC machining ensures that these parts are created with exacting standards, leading to improved performance and longevity of the final electronic product.

When it comes to precision machining, you can count on https://www.premiumparts.com/ for reliable CNC machining services that deliver superior results.

The CNC Machining Process: Step-by-Step Overview

CNC machining involves several key steps, each of which plays a crucial role in transforming raw materials into precision-engineered parts. Understanding these steps can provide insight into how CNC machining works and why it’s so effective. Here’s an overview of the typical CNC machining process:

1. Design and CAD Modeling

Before any machining takes place, the part design needs to be created. Engineers and designers use Computer-Aided Design (CAD) software to build a 3D model of the part. This digital model defines the geometry, dimensions, and tolerances of the part, serving as the blueprint for the CNC machine.

The design must be carefully planned to ensure that the part can be machined efficiently. The design software typically includes features for analyzing material properties, tool paths, and potential manufacturing challenges.

2. CAM Programming

Once the design is finalized, it is fed into Computer-Aided Manufacturing (CAM) software, which converts the CAD model into instructions that the CNC machine can understand. The CAM software creates the tool paths, which tell the CNC machine exactly where and how to cut the material.

The CAM software also accounts for factors such as feed rate, cutting speed, and tool selection, ensuring that the process is optimized for both speed and accuracy. This programming step is critical to achieving the desired results and ensuring minimal waste.

3. Machine Setup

Before the CNC machine can begin, it needs to be properly set up. This includes loading the raw material into the machine, securing it with clamps or fixtures, and installing the correct tools. Depending on the complexity of the part, multiple tools might be needed to complete different stages of the machining process.

The CNC machine is also calibrated to ensure that it operates within the specified tolerances. The machine operator may need to perform test runs to verify that everything is set up correctly before full production begins.

4. Machining the Part

Once the setup is complete, the CNC machine begins to cut the material. The machine follows the tool paths generated by the CAM software, carefully executing each cut, drill, or mill operation in sequence. CNC machines are typically equipped with multiple axes (usually three, four, or five), allowing them to perform complex movements and create intricate shapes.

The CNC machine moves the cutting tool along these axes, adjusting the speed, pressure, and direction of the tool to ensure that the material is cut precisely according to the design. During this phase, the part is gradually shaped, with excess material being removed layer by layer until the final geometry is achieved.

5. Inspection and Quality Control

Once the part has been machined, it undergoes thorough inspection and quality control procedures. Using advanced measuring tools, such as coordinate measuring machines (CMM), operators check the dimensions and tolerances of the finished part to ensure that it meets the required specifications.

Any deviations from the design are noted, and the part may be re-machined if necessary. Quality control is an essential part of the CNC machining process, as it ensures that each part meets the highest standards of precision and reliability.

6. Finishing and Post-Processing

In many cases, the part will require additional finishing or post-processing to improve its appearance, functionality, or performance. This might include surface treatments, such as anodizing, plating, or painting, or additional machining operations, such as deburring or polishing.

Post-processing ensures that the part is not only precise but also ready for its intended application. It also improves the aesthetics of the part, ensuring it meets the visual standards required by customers or industries.

Applications of CNC Machining: Where It’s Used

CNC machining is used in virtually every industry where precision manufacturing is required. Below are some of the most common applications:

Aerospace Components

In aerospace, CNC machining is critical for producing high-precision parts such as turbine blades, engine components, and landing gear. The components must meet strict regulatory standards and be capable of withstanding extreme conditions, which CNC machining can easily accommodate.

Medical Devices

Medical devices require the utmost precision, as even minor imperfections can have severe consequences. CNC machining plays a key role in the production of devices such as surgical instruments, implants, and diagnostic equipment. With its ability to work with a wide range of materials, including biocompatible metals and polymers, CNC machining is essential in the medical field.

Automotive Manufacturing

From engine blocks to exhaust manifolds, CNC machining is used extensively in the automotive industry. CNC machines can produce complex shapes with high precision, ensuring that the parts meet safety and performance standards.

Electronics and Consumer Goods

CNC machining is widely used in the electronics industry for producing small components such as circuit boards, connectors, and housings. The high level of precision ensures that these tiny components fit together seamlessly, contributing to the functionality and reliability of consumer electronics.

Tool and Die Making

CNC machining is also a vital tool in the creation of molds, dies, and tooling for other manufacturing processes. It allows for the production of highly detailed molds for injection molding, die-casting, and stamping processes, ensuring that the final products are manufactured with high accuracy.

Choosing the Right CNC Machining Service Provider

Choosing the right CNC machining service provider is critical to ensuring that your parts are manufactured with the highest quality and precision. When selecting a CNC machining company, consider the following factors:

1. Expertise and Experience

Look for a provider with years of experience in CNC machining. An experienced provider will be able to offer insights into the best materials, tools, and processes for your specific project. They will also have a proven track record of delivering high-quality parts on time and within budget.

2. Equipment and Capabilities

The company should have state-of-the-art CNC machines with advanced features such as multi-axis capabilities and high-speed spindles. The more advanced the equipment, the more complex and precise the parts they can produce.

3. Quality Control Standards

Quality control is essential in CNC machining. The provider should have strict quality assurance processes in place to ensure that every part meets the required specifications. Look for companies that use advanced inspection equipment, such as CMMs, to check the accuracy of each part.

4. Customer Support and Communication

Effective communication is key to ensuring a successful project. A good CNC machining provider should be easy to work with, offering timely responses to queries and updates on the progress of your order. They should also be transparent about lead times, pricing, and any potential issues that may arise during production.

5. Cost-Effectiveness

While it’s important not to compromise on quality, cost is always a factor. A good CNC machining provider should offer competitive pricing without sacrificing precision or quality. Look for companies that can provide cost estimates upfront and offer solutions to help reduce production costs.

Final Thoughts

CNC machining offers significant benefits, including unparalleled precision, speed, and efficiency. With its wide range of applications and ability to handle complex designs, it has become a cornerstone of modern manufacturing. Whether you’re in the aerospace, automotive, medical, or electronics industry, CNC machining can help bring your designs to life with exceptional quality and accuracy. By choosing the right CNC machining service provider, you can ensure that your parts are produced with the highest standards of craftsmanship, speed, and cost-effectiveness.