Unlocking the Future of Wastewater Treatment with MBBR Media Innovation

Introduction

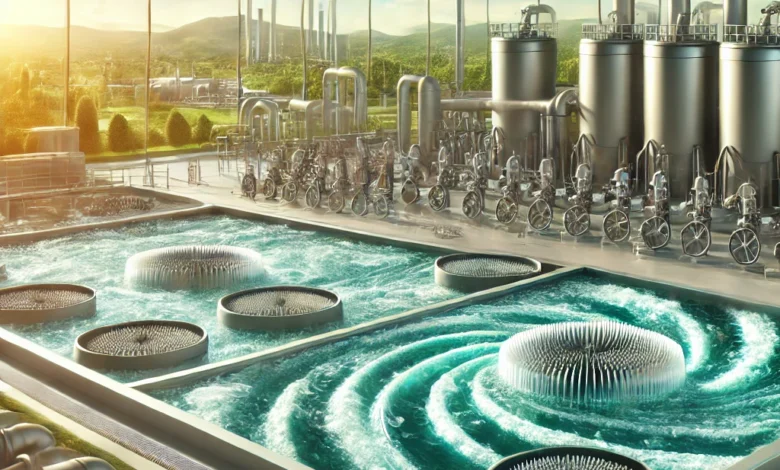

Wastewater treatment has always been a critical issue as populations grow and industries expand. The ability to clean and reuse water efficiently is becoming increasingly important. Traditional methods, while effective to some extent, often struggle to meet the demands of modern society in terms of both performance and environmental sustainability. There is a growing need for innovative technologies that not only improve the quality of treated water but also do so with minimal environmental impact. This is where the future of wastewater treatment starts to shift, thanks to the innovative approach offered by MBBR Media.

MBBR Media has revolutionized the way wastewater is treated by harnessing biofilm technology to maximize treatment efficiency in a compact space. As environmental regulations become stricter and water scarcity becomes more of a pressing global issue, it is essential to understand how MBBR (Moving Bed Biofilm Reactor) Media could be the key to unlocking a more sustainable future for water management.

What is MBBR Technology?

At its core, MBBR technology is a biological process designed for wastewater treatment. The system uses small plastic biofilm carriers—often referred to as media—to treat wastewater through a highly efficient process. These carriers provide a surface area for bacteria to grow and develop biofilms, which are crucial for breaking down organic pollutants.

The concept of biofilm-based wastewater treatment is not new, but MBBR takes it a step further by utilizing these moving carriers in a tank, allowing for a continuous, self-regenerating treatment process. This innovative approach makes MBBR one of the most effective wastewater treatment solutions available today, particularly in situations where space is limited or where conventional systems are unable to meet treatment requirements.

How MBBR Media Revolutionizes Wastewater Treatment

MBBR Media plays an integral role in the overall efficiency of the MBBR system. These media, usually made from high-density polyethylene, are designed with a high surface area-to-volume ratio, allowing for optimal biofilm growth. The constant movement of the media ensures that the biofilm is continuously exposed to fresh wastewater and oxygen, promoting rapid and efficient organic matter breakdown.

Unlike conventional activated sludge systems that require large volumes of space and significant amounts of energy, MBBR systems are compact and energy-efficient. The biofilm carriers move freely within the reactor, facilitating the effective treatment of wastewater without the need for excessive mechanical intervention. This results in both lower energy costs and a more reliable process.

To buy MBBR Media, visit https://www.mbbr-media.com/

The Science Behind MBBR Media

The treatment process in an MBBR system primarily relies on the biological activity of microorganisms present in the biofilm attached to the carriers. These microorganisms consume organic pollutants in the wastewater, breaking them down into simpler, less harmful compounds. The carriers’ design ensures that the biofilm has a protected surface on which to grow, while the movement within the reactor tank helps slough off excess biofilm, ensuring a consistent and balanced microbial population.

MBBR Media contributes to the reduction of both Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) in wastewater. These two metrics are crucial indicators of water quality, and reducing them means the water can be safely returned to the environment or reused for other purposes.

Advantages of MBBR Technology

The advantages of MBBR technology over traditional wastewater treatment methods are numerous. For one, MBBR systems require much less space compared to systems like activated sludge. This makes them particularly appealing for urban areas or industrial settings where space is at a premium. Additionally, because MBBR systems use biofilm carriers instead of relying solely on suspended microorganisms, they are more resilient to changes in wastewater composition and can handle higher loads of organic material.

Energy efficiency is another significant advantage. Since MBBR systems do not need the same level of mechanical aeration as conventional systems, they consume less energy. This makes MBBR technology not only more cost-effective but also more environmentally friendly, aligning with the global push toward sustainable energy use.

Environmental Impact of MBBR Technology

MBBR technology offers a low-carbon solution to wastewater treatment, significantly reducing the environmental footprint compared to other methods. The reduced energy consumption translates directly into lower greenhouse gas emissions. Moreover, the high treatment efficiency of MBBR systems makes them ideal for water-scarce regions, where the ability to treat and reuse wastewater can help mitigate the impacts of drought and water shortages.

By incorporating MBBR Media, wastewater treatment plants can enhance their capacity to handle fluctuating wastewater loads without compromising the quality of the treated water. This ensures that even in times of high demand, water resources can be managed responsibly, reducing the strain on natural ecosystems.

Applications of MBBR Media in Wastewater Treatment

MBBR Media has been widely adopted across various sectors due to its versatility. One of its primary applications is in municipal wastewater treatment, where it helps cities manage large volumes of wastewater efficiently. The technology is also extensively used in industrial wastewater treatment, where the composition of the wastewater can be more complex and challenging to treat with traditional systems.

Beyond large-scale applications, MBBR technology is also finding its place in residential settings, particularly in areas where decentralized water treatment systems are necessary. This scalability makes MBBR a highly flexible solution, suitable for use in a wide range of environments.

Comparing MBBR with Other Technologies

When compared to other wastewater treatment technologies, MBBR consistently stands out for its compactness and efficiency. For example, the Activated Sludge Process (ASP) is highly effective but requires significantly more space and energy to operate. MBBR systems, on the other hand, pack a higher treatment capacity into a smaller footprint.

Similarly, while Membrane Bioreactor (MBR) technology is praised for its ability to produce high-quality effluent, it often comes with higher operational costs and maintenance requirements. In contrast, MBBR technology offers a simpler, more robust solution without the need for complex filtration systems.

Key Components of an MBBR System

The key to a successful MBBR system lies in the biofilm carriers. These small, often cylindrical media are engineered to provide the maximum surface area for biofilm growth while allowing for free movement within the reactor. In addition to the carriers, aeration systems play a crucial role in supplying the oxygen needed for microbial activity, while clarifiers help separate treated water from any remaining solids.

MBBR Media in Action: Case Studies

Several case studies demonstrate the effectiveness of MBBR Media in real-world applications. In one instance, a municipal wastewater treatment plant was able to double its treatment capacity without expanding its physical footprint by retrofitting its existing system with MBBR technology. In another example, an industrial facility successfully reduced its chemical oxygen demand by over 80% using an MBBR system, helping the company meet stringent environmental regulations.

Innovations and Future Trends in MBBR Media

The future of MBBR technology looks bright, with several exciting innovations on the horizon. Researchers are constantly working on improving the design of biofilm carriers to increase efficiency and reduce costs. In addition, the integration of artificial intelligence (AI) and the Internet of Things (IoT) is allowing for more automated and precise control of MBBR systems, further enhancing their performance.

As global water scarcity becomes a more pressing concern, MBBR technology is expected to play an increasingly vital role in water reuse and resource recovery efforts. The trend toward energy-efficient, automated systems ensures that MBBR will continue to be at the forefront of wastewater treatment innovation.

Challenges in MBBR Implementation

Despite its numerous benefits, implementing MBBR technology is not without challenges. Initial setup costs can be higher than for conventional systems, although this is often offset by long-term savings in energy and maintenance. Additionally, in certain climates, biofilm growth can be slower, requiring more careful management of the system’s operational parameters.

Long-term maintenance can also be an issue, as biofilm carriers need to be monitored to ensure that they are performing optimally. Over time, carriers can become clogged or coated with excess biofilm, which may reduce treatment efficiency if not properly addressed.

Why MBBR is the Future of Wastewater Treatment

As environmental regulations become more stringent and the demand for clean water continues to rise, MBBR technology is uniquely positioned to meet these challenges. Its ability to provide high-quality treatment in a compact, energy-efficient package makes it a viable solution for a wide range of wastewater treatment applications.

Governments around the world are beginning to recognize the potential of MBBR technology, offering policy incentives for its adoption. With its proven ability to reduce energy consumption and improve water quality, MBBR technology is set to become a key player in the global push toward sustainable water management.

How to Choose the Right MBBR System for Your Needs

When selecting an MBBR system, several factors should be taken into account. The size and nature of the wastewater being treated, the available space, and the long-term operational goals of the facility are all important considerations. Additionally, it is important to choose a system that is scalable and adaptable to changing needs.

For facilities handling high volumes of wastewater, larger biofilm carriers or multiple reactors may be necessary. Conversely, for smaller operations, compact systems with smaller media can provide the same level of treatment in a reduced footprint.

Conclusion

MBBR Media is paving the way for a new era in wastewater treatment, offering a sustainable, efficient, and scalable solution to one of the world’s most pressing environmental challenges. With its ability to handle fluctuating wastewater loads, reduce energy consumption, and minimize space requirements, MBBR technology is well-suited to meet the needs of both industrial and municipal wastewater treatment plants. As innovations continue to emerge, and as more facilities adopt this cutting-edge technology, the future of wastewater treatment looks increasingly promising.